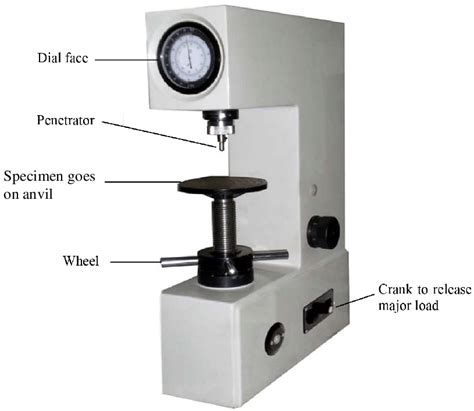

limitations of rockwell hardness testing|rockwell hardness testing instructions : mail order Watch on. What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material .

Electric Pressure Cooker eschmann SES2000 Service Manual 46 pages Laboratory Equipment eschmann Little Sister SES 2010 User Manual 42 pagesSES 2000 AUTOCLAVE Part 3 PART 3 MAINTENANCE Air Valve (Fig. 3, item 6) Fit leaf spring (4) to microswitch actuator lever (5), with clamp screw (6) and washer (7). The air valve is fitted in the manifold at the rear of the sterilizing .

{plog:ftitle_list}

Get the best deals on Autoclave (Steam Sterilizer) Autoclaves & Sterilizers when .

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different .The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a .

Disadvantages of the Rockwell Hardness Test 1. Limited Applicability to Soft Materials. The Rockwell Hardness Test may not be suitable for accurately measuring the hardness of very . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .There are different reasons for this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, .

Watch on. What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material .The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a slight error in measuring the depth difference can result in a significant error in the calculated hardness value. Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. Rockwell Hardness Test. While hardness .

Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery .The Rockwell test method is used on all metals, except in condition where the test metal structure or surface conditions would introduce too much variations; where the indentations would be .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a .

rockwell hardness testing procedure pdf

Disadvantages of the Rockwell Hardness Test 1. Limited Applicability to Soft Materials. The Rockwell Hardness Test may not be suitable for accurately measuring the hardness of very . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary .There are different reasons for this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, .Watch on. What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a slight error in measuring the depth difference can result in . Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. Rockwell Hardness Test. While hardness .

Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery .

The Rockwell test method is used on all metals, except in condition where the test metal structure or surface conditions would introduce too much variations; where the indentations would be .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, .The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a .Disadvantages of the Rockwell Hardness Test 1. Limited Applicability to Soft Materials. The Rockwell Hardness Test may not be suitable for accurately measuring the hardness of very .

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary .There are different reasons for this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, .Watch on. What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material .The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a slight error in measuring the depth difference can result in .

Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. Rockwell Hardness Test. While hardness . Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery .

rockwell hardness testing procedure

This range is designed with price and economy in mind – the ECO range offers all the functionality of Astell’s standard circular range of autoclaves, but with an increased usable capacity due to a square chamber design.Browse Item # SSL20, Low Pressure Connection Sleeve in the Parker / Autoclave Engineers .

limitations of rockwell hardness testing|rockwell hardness testing instructions